摘要

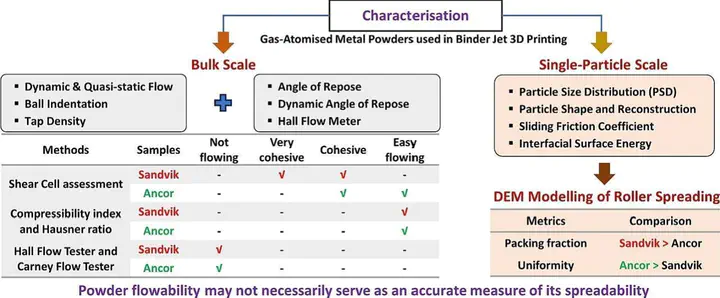

A comprehensive characterisation study has been undertaken to examine the flowability and spreadability of two distinct types of gas-atomised metal powders used in Binder Jet 3D printing technology. The experimental characterisation encompasses an analysis of the physical properties of individual particles as well as the flow behaviour of bulk powder. The data gathered from individual particle analysis are subsequently employed in numerical simulations of roller spreading by Discrete Element Method (DEM) to gain valuable insights into the intricate interplay between powder attributes and its spreading characteristics. The findings reveal that employing bulk characterisation tests, such as shear cell tests and compressibility indices, results in contradictory outcomes. Moreover, the spreadability data derived from the DEM simulations do not exhibit a strong correlation with the results obtained from the characterisation of the bulk powder. These results underscore that the flowability of the powder may not necessarily serve as an accurate measure of its spreadability when applied in thin layers for additive manufacturing. This study further establishes a crucial connection between the intrinsic properties of individual particles and the collective behaviour of particles within the bulk material.