摘要

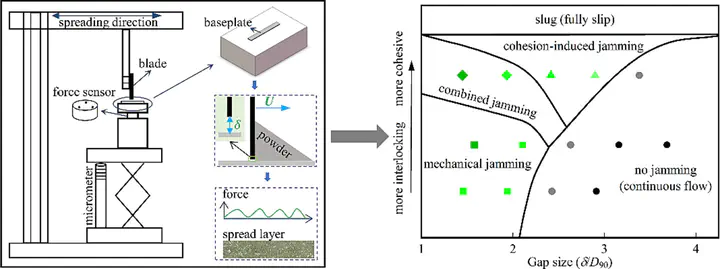

This work focuses on a new kind of jamming of particle flow through constriction, which occurs in the powder spreading process in additive manufacturing, i.e. a powder heap is spread onto a rough surface by a moving blade. This work shows the experimental evidence of transient jamming by blade spreading at the first time. The jamming repetitively forms and collapses under the combined effects of narrow gap and blade shearing action. Angular particles with weak cohesion are more prone to mechanical jamming, with longer survival time of jammed state and stronger jamming strength. Besides mechanical jamming, cohesion-induced jamming is also responsible for the formation of empty patches within the spread layer. A regime map is deduced from physical experiments for the transient jamming by blade spreading in additive manufacturing, depending on the gap size, particle shape, and particle cohesion.