Analysis of the metrics and mechanism of powder spreadability in powder-based additive manufacturing

摘要

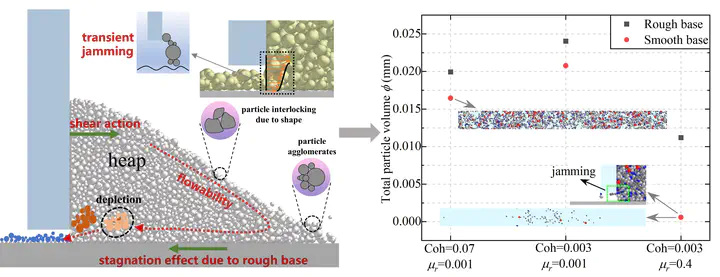

Powder spreadability is critical to particle spread layer and thus the quality of final product in powder-based additive manufacturing, but the metrics and the underlying mechanics have not yet been well acknowledged. In this work, the metrics of spreadability are examined for powder with different size classes, and the factors affecting powder spreadability are analysed, in which both the cohesion and interlocking of particles are included. The simulation results are validated by comparing the total particle volume of spread layer against the experimental and numerical data in previous work. The results show that relative powder spreadability should be compared at the same ratio of the gap height to particle size, especially for the powders with different particle size classes. Powder spreadability is mainly controlled by the shear action of the blade on the heap, the stagnation effect due to rough surface of substrate, particle jamming around the gap region, and the effect of powder flowability on the movement of particles within the heap. Jamming makes powder spreadability different from powder flowability. As particle jamming is more prone for the particles with strong interlocking, powder spreadability is more sensitive to the rolling friction than the cohesion of particles, especially for the substrate surface with small roughness, although the rheological behaviour of bulk particles is similar in front of the gap. A physical model is proposed to predict the maximum fraction of spread layer at the specified gap height.